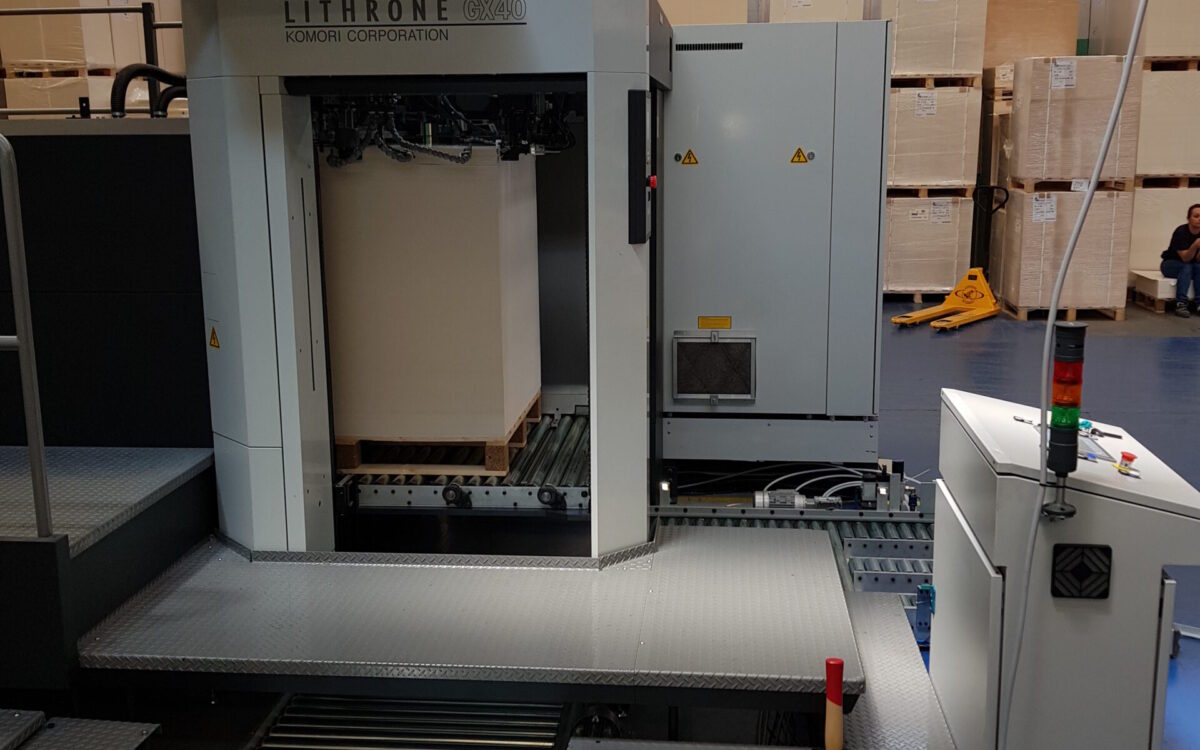

Pallets Handling and Lifting

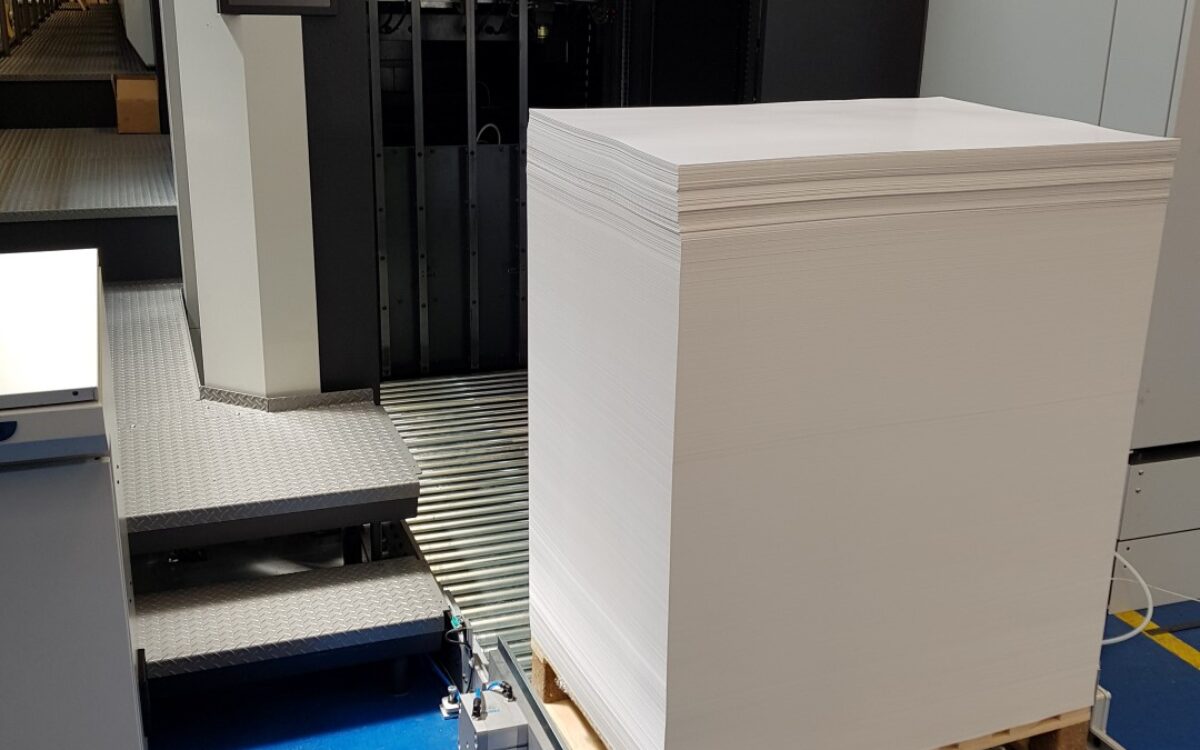

The Risetec PRESS PRO is designed to allow printing already presses fitted with lifting tines or forks in the feeder and enabled for non-stop operation to print continuously without stopping to change pallets of paper at the feeder. It is particularly beneficial where thicker stocks are frequently used (such as in packaging), longer runs are common and/or for work-and-turn and, in conjunction with a pallet turner, work-and-tumble jobs – especially where the press is equipped with in-line drying.The consequent reductions in downtime,reduction of lead times and maximization of productivity can contribute significantly to profitability and returns on capital investments. The Risetec PRESS PRO system aligns the full pallet to be delivered into the press feeder in the correct position.The press’s forks are automatically inserted into the dimished existing pile when triggered by a photocell, the platform drops and the previous pallet is ejected before the new pallet is advanced into position. It is then raised automatically to the remainder of the previous pile and micro-aligned before the the forks are removed. When the new pile is reduced to the chageover amount, the photocell triggers the process to be repeated.